Introduction to Food Waste

Intentionally dumping milk provided a heart-rending illustration of COVID disruptions in the food supply chain.

However, even before COVID, one third of food was being wasted throughout the food supply chain. For perspective this represents:

- 3 times more food than it would take to feed the 1/9th of people who are undernourished (granted there are associated logistics issues)

- The second largest potable water consumer on earth is water to used to grow wasted food

- If it were a country, food loss would be the 3rd largest GHG emitter on the planet (after USA & China)

- Globally, lost food accounts for $990 trillion in lost economic value, and

- Conversion of additional land to agriculture (such as burning Amazon forest) to replace lost food is a leading contributor to the loss of species (biodiversity)

According to Second Harvest, a total of 47% of food loss and waste occurs in manufacturing and processing step. Most people assume that most manufacturing efficiency gains have already been secured; however, this is not the case.

For example, Campbells has been making soup for over 100 years, has a continuous improvement team, and annually completes solid waste audits. Even so, by collaborating with our sustainability engineers, 6 measures were found that could collectively avoid the loss of 980 tonnes/yr of food (valued at $706,000/yr). This project was selected as the top clean capitalism project in Canada and inspired Walmart Foundation to co-fund food loss prevention demonstration assessments at 50 food & beverage processors across Canada saving an average of $230,000/yr/facility of food (Globe & Mail), which also won a national award.

Champions 12.3 10x20x30 Initiative

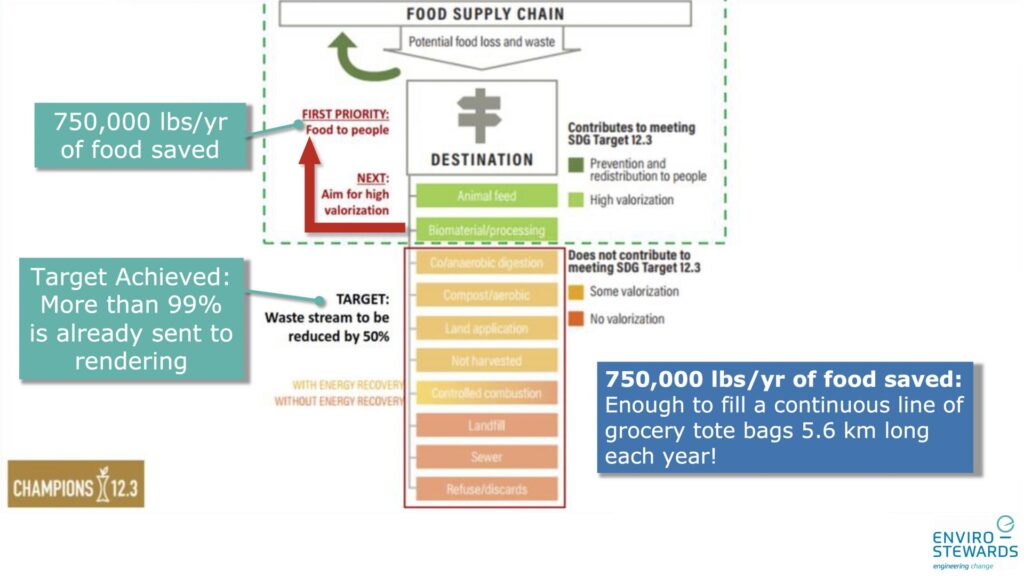

Ten of the world’s biggest food retailers are launching the Champions 12.3 10X20X30 initiative to engage 20 of their priority suppliers to aim to reduce their amounts of food loss and waste by half by the year 2030. As several of our clients were invited to participate, we prepared a case study to demonstrate how to generate value and report food savings under this framework.

A protein processing facility in the USA was already diverting over 99% of their food loss to rendering. Cutting the remaining <1% in half would have had a very small economic, social, and environmental benefit. However, by reducing the amount of food lost to rendering in the first place, they could have a substantially larger beneficial impact.

Following an assessment by Enviro-Stewards and facility team members, the facility was able to modify equipment and procedures to reduce the amount of food lost to rendering by 1/3. This saved 356 tonnes (784,640 lbs) of top-quality product during 2019 (when compared to the 2017 baseline).

In addition to financial savings of more than a half million dollars per year, this saved food:

- is enough for 3,140,000 protein servings per year

- avoids the loss of 1,960 tonnes/yr of embedded greenhouse gas (GHG)

- and saves the 2.1 million cubic metres (565 million gallons) of water footprint required to make this food.

Introduction to food loss and waste at food & beverage manufacturers

Enviro-Stewards has been a leader in helping the food and beverage industry understand and minimize the impact that food loss and waste has on our planet by quantifying the greenhouse gas (GHG) emissions associated with food waste at the processing level. Food and beverage manufacturers (i.e. bakeries, breweries, meat processing, etc.) generally focus on Scope 1 and 2 emissions at the processing level. Examples of Scope 1 emissions include natural gas and diesel combustion, and Scope 2 emissions are typically associated with electricity usage. However, GHG emissions do not occur exclusively at the processing level. As outlined in the Smithfield example above, a significant portion of the emissions have already occurred by the time raw materials (food ingredients) arrive at the processing facility. This means that preventing food loss and waste at the processing level can have a significant impact on the GHG emissions in your supply chain (by avoiding the loss of previously embedded GHG).

This blog post discusses why food and beverage manufacturers should focus on food loss and waste, how to address the problem, and how Enviro-Stewards can help.

Where are Greenhouse Gases emitted in your supply chain?

Before raw materials (food ingredients) even arrive at your facility, an average of 70% of GHGs have already been emitted (this value is a global average and does not include emissions associated with transport, which on average is 13% of emissions). The global average percentage of GHGs emitted prior to processing for select food ingredients is shown in Figure 1. The sources of these emissions are a result of land-use change effects (such as deforestation to make space for farming), farming, and animal feed. On average, processing accounts for 5% of emissions. Therefore as a food and beverage manufacturer, reducing food waste within your facility can make a larger impact on your carbon footprint than focusing strictly on Scope 1 and 2 emissions from your facility (because by reducing food waste you’re avoiding the upstream GHG emissions associated with the production of your input ingredients).

Figure 1 – Global Average Percentage of Emissions Before Processing (Land use change, animal feed, and farm). Data adapted from Poore, J., & Nemecek, T. (2018). Reducing food’s environmental impacts through producers and consumers. Science, 360(6392), 987-992.

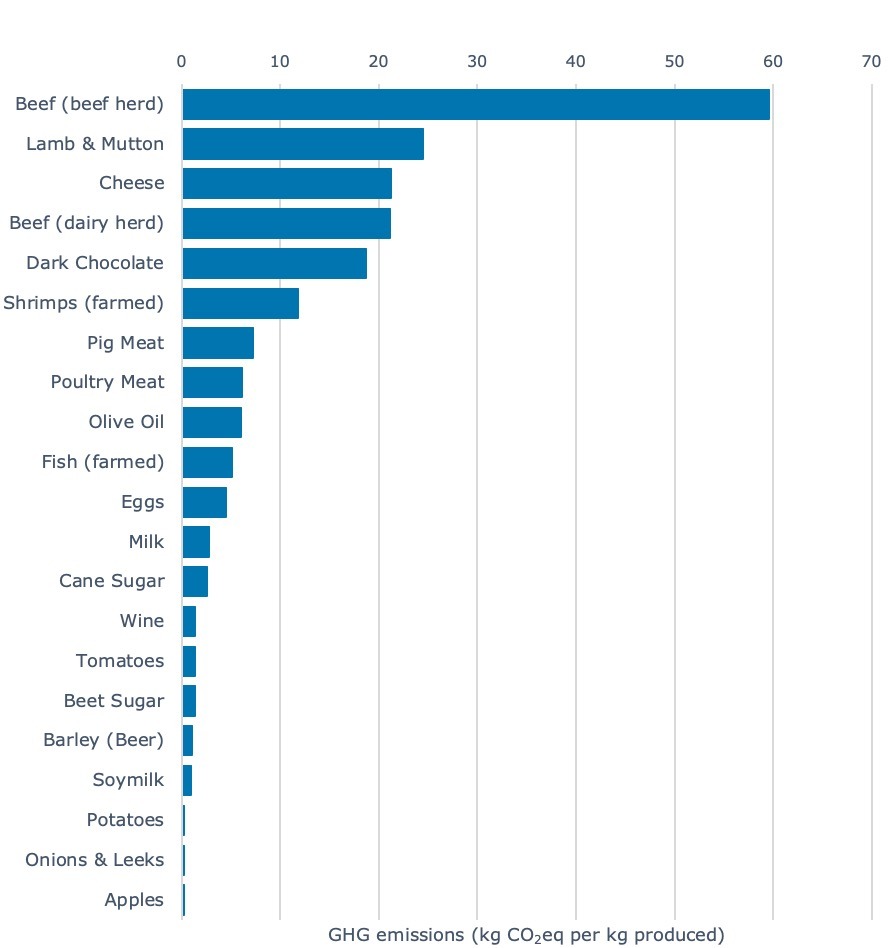

Figure 2 – Global average GHG emissions per kg of select food ingredients. Data adapted from Poore, J., & Nemecek, T. (2018). Reducing food’s environmental impacts through producers and consumers. Science, 360(6392), 987-992.

Figure 2 shows the global average GHG emissions per kilogram of the select food ingredients from Figure 1. As an example, consider a theoretical medium-sized pork sausage manufacturing facility that produces 8,000 tonnes of sausage annually with a misaligned conveyor system that causes 40 kg per of sausage day to be lost to the floor and discarded. This theoretical facility emits 180 tonnes of Scope 1 and 2 GHGs (from natural gas combustion and electricity consumption). Forty kilograms of sausage may not seem like a substantial amount to lose (40 kg is enough to fill a garbage bin); however, over the course of a year this loss will total 10 tonnes of sausage. Based on data from the Figure 2, 6.1 kg of carbon dioxide equivalents per kg of sausage (CO2eq/kg) are attributable to the sausage before the processing stage. Hence, the GHG emissions from the discarded sausages before the pork meat arrived at the facility is 61 tonnes of CO2eq. This equates to one-third of the Scope 1 and 2 emissions from the facility, demonstrating how avoiding food waste can have a substantial environmental impact. For more information, this blog describes our approach to food loss and waste and its beneficial environmental and economic impacts.

Why food and beverage manufacturers should focus on food waste: Environmental benefits

As mentioned above, the global food supply chain accounts for 13.7 billion tonnes of CO2 equivalents (Poore and Nemeek, 2019), which is a staggering 26% of anthropogenic GHG emissions. In order to limit global warming to a 1.5OC increase from pre-industrial levels, global carbon emissions must fall to 55% of 2010 levels by 2030 and continue a steep decline to zero net emissions by 2050 (per UNSDG #13). Therefore, to minimize the environmental impacts of the food supply chain and meet the goals established by UNSDG 13, a strong focus should be placed on eliminating food loss and waste within manufacturing facilities.

Why food and beverage manufacturers should focus on food waste: Financial benefits

In addition to the devastating impacts that food waste has on the environment, there are significant financial factors to consider as well. Increasingly, consumers want to know that the products they purchase are having a minimal impact on the environmental. In a study by Coleman Parkes Research, 47% of surveyed consumers said they wanted to do business with environmentally conscious retailers. Taking demonstrable, quantifiable actions on food waste can help drive sales and grow your business with a competitive advantage over less environmentally focused food and beverage manufacturers.

Furthermore, there is a cost associated with disposing food waste that is frequently under-accounted. For example, at one brewery that Enviro-Stewards worked with, the disposal cost of sending a unit of beer to the drain (to be treated by the municipal wastewater treatment system) was 5 times less than the value of the value of the lost beer that was causing this sewer surcharge.

In another example, a pie producer only considered the cost of having its waste bin emptied by its waste contractor. In total, 5 pies were lost per hour, which might not seem like much. However, at 32 hours per week, 52 weeks per year, this results in 8,300 pies lost annually. Assuming each pie has a retail price of $3.50, this food loss is worth $29,000. In comparison, the disposal cost for this food loss was estimated to be less than $360. Avoiding that waste in the first place results in fewer raw materials required by the factory to compensate for the wasted pies and reduces the carbon footprint of the factory as a result of fewer Scope 3 emissions. Alternatively, if there is enough demand such that those pies could have been sold, $29,000 in additional revenue would be obtained by the facility at no additional cost while also saving $360 on the cost to dispose of the pies.

How big is the food waste problem?

As previously mentioned, 47% of food loss and waste occurs in manufacturing and processing. In Canada alone, this represents 16.7 million tonnes of food that is wasted in these two steps of the supply chain. To help visualize how massive this quantity is, it’s the equivalent to the mass of 141 CN Towers.

Globally, a third of all food produced for human consumption is wasted. This means that food waste is responsible for 4.5 billion tonnes of GHG emissions (33% of the 13.7 billion tonnes figure mentioned earlier). That means if global food waste was its own country, it would be the third largest carbon emitter in the world behind only China and the United States.

How can food processors avoid food waste?

There are several steps that food processors can take to tackle this issue. The first step would be to understand the scope of the problem in the context of your facility by keeping track of food waste. Enviro-Stewards has found that the most common next step that facilities take is to then spend time and money to find the best place to dispose of that waste, such as in a biodigester, as animal feed, or to a waste bin. However, a significant cost has already been expended to purchase the raw materials, and furthermore, GHGs have been emitted just for those raw materials to arrive at the facility (not to mention the time and resources required to process those materials until the stage in processing where they were wasted). Therefore, instead of finding the best way to dispose of the waste, the Enviro-Stewards preventative approach involves focusing on the root cause of the source of food loss and waste and implementing procedures or engineering controls that will eliminate it. Put simply, if the waste is not created in the first place, there is no need to explore ways to dispose of it.

One often forgotten place to look for food loss and waste (especially for beverage processors) is product that goes down the drain. Wastewater treatment is an expensive cost to processors that may even require constructing and operating an on-site treatment facility. This can be mitigated with Enviro-Stewards’ preventative approach. For example, Fruition Fruit & Fills was seeking a solution to meet their local by-law’s effluent discharge requirements. The next step for most processors is to build a biological treatment plant. Alternatively, Fruition Fruit & Fills retained Enviro-Stewards to find a more economical solution. For Enviro-Stewards, the next step was to take a preventative approach and explore and address root causes of the effluent loading. This approach identified practical affordable actions that could be implemented at the process level, thereby eliminating the need for a treatment facility. Once implemented, these solutions reduced loading to the sewer by 80%, reduced waste sent to landfill by 70%, and reduced GHG emissions by 30%.

The differentiating step of considering “Why is there food waste?” instead of “Where do I put this food waste?” can have significant impacts, as demonstrated by the Fruition Fruit & Fills success story. Once the food waste has been measured, the next step in the Enviro-Stewards approach is to understand why that food waste occurred and how to prevent it from occurring to keep the food as sellable product.

Another success story (featured in this CBC article) using Enviro-Stewards’ methodology was a food loss and waste assessment at Beau’s Natural Brewing Co. (Beau’s), Canada’s largest certified organic craft brewery and a certified B Corporation. The food loss management practices that were already in place at the brewery focused on finding somewhere to put the waste, such as reusing spent brewers’ grain as cattle feed and diverting spent yeast and organic by-products to a biodigester to create energy to run a local farm. Additionally, the existing wastewater treatment system was unable to process the brewery’s increasing effluent strength and Beau’s was considering expensive upgrades to it. With support from the Commission for Environmental Cooperation (CEC), Enviro-Stewards assessed the brewery for preventable food loss and waste. The preventative assessment found 395,000 litres of beer that was being lost to the drain. Avoiding that beer loss through the recommended measures in the assessment report represents a 7.4% growth in production without having to increase expenditure on raw materials, facility expansion, or additional labour. As Steve Beauchesne, CEO and co-founder of Beau’s puts it, “Preventing food loss furthers our goal of being a force for good while also improving our financial performance, which will allow us to continue to grow and thrive.” By reducing its food waste, Beau’s is now capable of growing in capacity and saving financially without increasing its carbon footprint.

Why prevent food waste?

Enviro-Stewards is a leader in the prevention of food loss and waste. In 2019, we completed a project with Provision Coalition Inc. to identify practical food loss and waste prevention opportunities at 50 food and beverage manufacturing facilities in Canada. Cumulatively, the assessments identified 9.3 million kg/year of avoidable food loss and waste, worth $11.4 million/year. The environmental impact is significant as well. As discussed earlier, most GHG emission associated with food have already been emitted by the time it reaches the processing stage. The food waste identified at the 50 facilities emitted 32,600 tonnes of CO2eq. This project received an award for clean capitalism from Clean50.

The reach we were able to achieve through the project spanned multiple industries: breweries, bakeries, dairies, poultry, beef, pork, and frozen foods. We partnered with facilities with as few as 5 employees to as many as 500-plus. Enviro-Stewards is now completing a circular food economy demonstration project in Guelph Ontario to help tackle food loss and waste. This next step is looking at integration resources between manufacturers to explore ways to re-purpose unavoidable food waste. For example, bread waste from a bakery could be used to brew beer at a brewery, and spent grains from that brewery could be used to make bread at the bakery.

Our reach and extensive work within many types of food and beverage facilities allow us to innovate creatively with practical solutions to minimize or reduce food loss and waste (in addition to identifying ways to reduce utility consumption).

If you have any questions or would like to discuss your food loss and waste needs, please feel free to contact us.