Sustainable manufacturing is leading the revolution in the world of green industry as it transforms conventional production methods into greener ones. This approach uses resources more efficiently (saving costs) and cuts down on environmental harm (reducing environmental footprints).

As the world’s industries try to lessen their harm to the environment and achieve sustainability goals, going green (and doing so credibly) is key. Sustainable manufacturing is a step towards a greener, stronger industrial future.

Key Takeaways from this Blog:

- Sustainable manufacturing integrates eco-friendly processes into traditional production.

- Environmentally conscious manufacturing enhances resource efficiency.

- Adopting sustainable practices reduces ecological footprints and operational costs.

- Sustainable manufacturing fosters a resilient, eco-friendly industrial future.

- Measuring and tracking your sustainability performance will help provide your customers with the environmental metrics they need for their own sustainability reporting.

Understanding Sustainable Manufacturing

Environmentally-conscious manufacturing focuses on reducing harm to the environment by using resources wisely. However, this approach can also provide economic benefits to companies since costs are tied to the consumed resource. Later, we’ll illustrate a few examples of this from our experience where following these principles helped facilities remain competitive and maximize profit while reducing their environmental footprint.

Other terms that you may have heard can also be considered under the umbrella of sustainable manufacturing, would include:

- Pollution Prevention (P2)

- Cleaner Production

- Lean and Clean

- Resource Conservation

- Holistic Assessment

The bottom line with all the above terms is to minimize consumption and waste at source rather than focusing on end-of-pipe solutions. For example, Jackson Triggs’ facility in Oliver, BC, needed to install a wastewater treatment system as its effluent was consuming most of the town’s treatment capacity. A conventional approach would just focus on building a treatment system to deal with the end-of-pipe effluent loading. However, a sustainable manufacturing approach would employ P2 principles to first minimize waste at source before evaluation of treatment solutions. As a result of Enviro-Stewards’ P2 assessment of the winery, we identified opportunities to reduce organic loading to the drains by two-thirds and cut the volume of wastewater in half. By addressing the effluent loadings and water uses at-source (i.e., at the equipment and process level), the reductions translated into a capital cost savings of 50% for the treatment system because it only had to treat the remaining third of the facility effluent. You can view and download this case study here.

Key Components of Sustainable Manufacturing

The path to eco-friendly production involves several key drivers. These include optimizing resource use, reducing waste, minimizing use of toxic substances, and employing renewable energy. Each plays a big role in making industries more sustainable and greener, as we’ll see below.

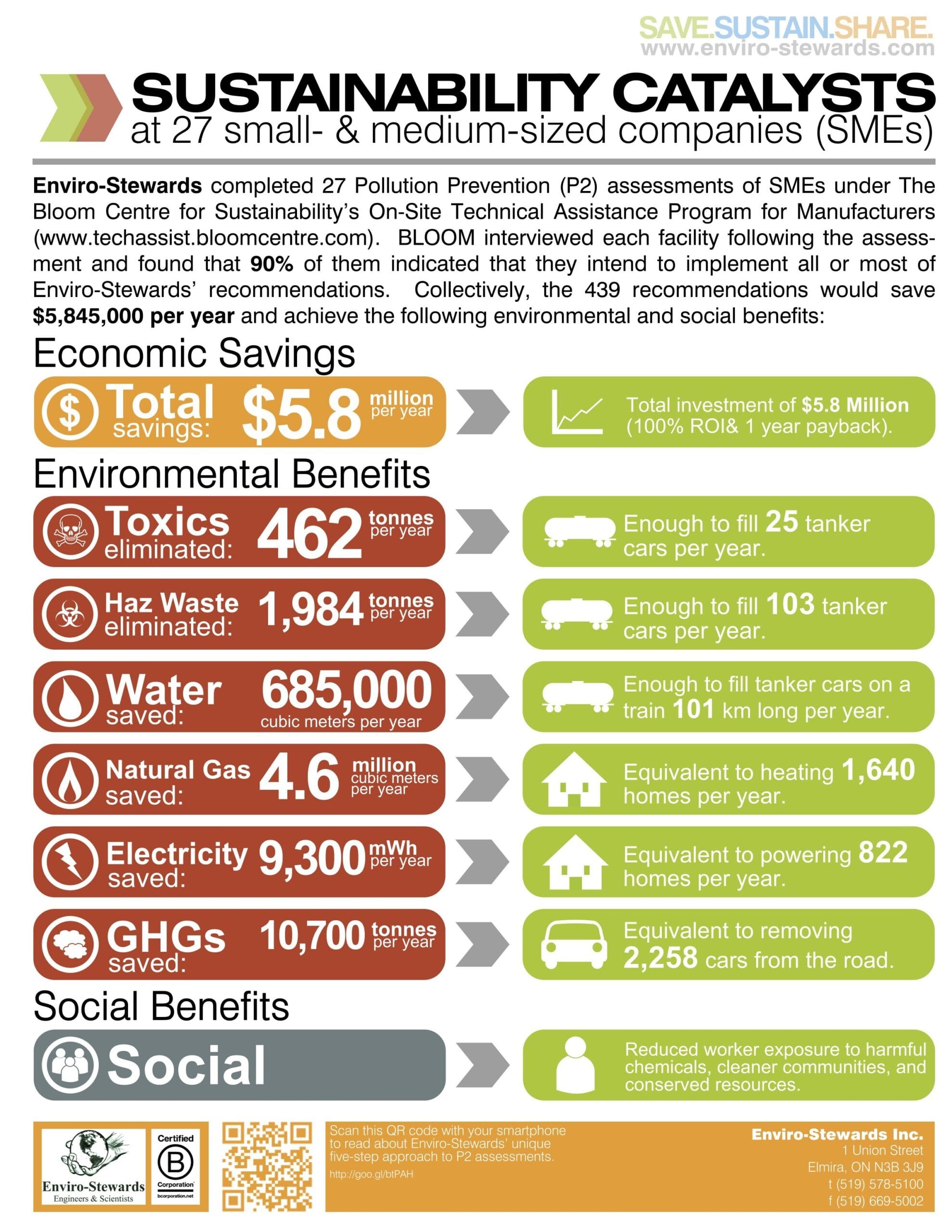

Enviro-Stewards completed sustainability assessments at 22 small- and medium-sized enterprises (SMEs), the results of which collectively illustrate the environmental and economic value of sustainable manufacturing. Let’s take a brief look below at these benefits.

Resource Efficiency

Using resources more efficiently, like electricity, natural gas, and water, is key to lowering environmental impact and utility spend. Although we encourage the adoption of renewable energy technologies such as wind and solar, it’s even more important to reduce your energy use as much as possible first – or else you’ll just be wasting your energy more efficiently!

Through a sustainable manufacturing approach, the total resource savings of the 22 facilities that were assessed included:

- 7,600 mWh per year in electricity use (equivalent to powering 672 homes per year)

- 3 million m3 of natural gas per year (enough to heat over 1,000 homes per year)

- 595,000 m3 of water per year (enough to fill tank cars on a train 88 km long per year

The economic benefit associated with the above resource savings totaled over $4 million per year with a 100% ROI and a 1-year payback.

Toxics Use & Hazardous Waste

The 22 sustainability manufacturing assessments collectively generated the following reductions in toxics use and hazardous waste generation.

Waste Reduction

Reducing waste is vital for your carbon footprint reduction. Recycling, reusing materials, and circular design help a lot. These steps save resources, cut costs, and reduce pollution.

Eliminating or reducing food loss & waste (FLW) is a significant sustainable manufacturing opportunity for food & beverage facilities. Due to GHGs embedded in food – from farm to processing to your fridge – reducing FLW can have significant environmental and financial benefits (especially for reducing Scope 3 emissions). In fact, food waste is the third-largest GHG emitter on the planet!

For an example of savings, a FLW study of 50 Canadian food & beverage processors collectively found measures to save:

- 32,600 tonnes of embedded CO2e emissions each year (equivalent to taking 7,000 cars off the road).

- An average of $230,000 of annual savings per facility with a payback of less than one year (this is enough to materially improve the competitiveness and profitability of each of these facilities)

Use of Renewable Energy

Using renewable energy is crucial for sustainable manufacturing now and into the future (it’s expected to make up 27% of global energy by 2030). Adding solar and wind power to operations cuts fossil fuel use and emissions, which supports environmental goals and saves money in the long run. However, we always recommend starting with conservation first before exploring renewable energy technologies.For example, one winery we worked with, Southbrook Vineyards, was able to install fewer solar panels thanks to conservation measures they implemented based on our energy efficiency assessment (read the full case study here).

Innovative Green Manufacturing Processes

Companies are now focusing on sustainable production methods. They use technology, efficiency, and sustainability to change the industrial world. Lean manufacturing is a key part of these green processes.

Lean (and Clean) Manufacturing

Lean manufacturing improves operations by cutting waste while boosting productivity. An innovation for sustainable manufacturing is the concept of “Lean & Clean”, which marries the productivity improvements of lean manufacturing with the environmental benefits of green manufacturing – both of which can yield financial savings.

A Lean & Clean study conducted by CME (lean portion) and Enviro-Stewards (clean portion) at Carlson Engineered Composites identified several lean and clean opportunities that recommended opportunities to improve efficiency and conserve resources (water, energy, solid waste, and air emissions reductions). The case study provides further details.

| Aspect | Lean & Green Manufacturing | |

| Resource Utilization | Not closely tracked, which can lead to high wastage | Optimized usage, continuous improvement |

| Energy Consumption | Often higher than necessary | Reduced |

| Real-Time Data | Limited | Advanced (time studies and tracking software) |

| Negative Environmental Impact | Often unknown, can be significant | Minimized |

Benefits of Adopting Sustainable Practices

Implementing sustainable manufacturing practices has many benefits for the environment and your business: It helps reduce your carbon footprint and conserve natural resources while saving money. This is good for both the planet and your company.

Environmental Conservation

Making your manufacturing processes sustainable is key to reducing its environmental impact on the environment, as it cuts down on waste and energy use. This, in turn, helps reduce pollution and conserves natural resources.

Cost Savings

As previously mentioned, environmentally conscious practices also save money because using less energy and consuming fewer resources lowers your utility costs. Plus, they make your operations more efficient, further improving profitability.

Looking at the financial side, sustainable vs. traditional manufacturing shows big differences:

| Aspect | Sustainable Manufacturing | Traditional Manufacturing |

| Energy Costs | Reduced due to energy-efficient technologies | Higher due to inefficient energy use |

| Waste Management | Lower costs through waste reduction techniques | Higher costs due to more waste production |

| Resource Utilization | Optimized for efficiency | Often inefficient and wasteful |

| Regulatory Compliance | Higher compliance, fewer penalties | Higher risk of penalties due to non-compliance |

Role of Renewable Energy in Manufacturing

Renewable energy is becoming key in manufacturing as companies move towards green practices and try to achieve sustainability goals, like decarbonization or net zero. Most people are already familiar with conventional types of renewable energy technologies, like solar panels and wind turbines. A unique sustainable manufacturing technology that is low impact design (LID) and saves water and energy is a blue roof. A blue roof collects and stores rainwater on a facility’s roof, which attenuates stormwater flow to stormwater sewer systems, thereby reducing the risk of flooding. However, the stored water can also be used for irrigation, to flush toilets, and for other non-potable applications (like rinsing or non-contact cooling). Furthermore, blue roofs can even save energy, as the evaporation of the water from the roof cools the building, reducing cooling demands. We were fortunate to be part of the project team that helped design and implement Credit Valley Conservation’s (CVC) blue roof. Enviro-Stewards installed the original smart blue roof on its headquarters in Elmira, Ontario.

How Industry 4.0 Technologies Enhance Sustainability

How Industry 4.0 Technologies Enhance Sustainability

Using Industry 4.0 technologies helps make businesses more eco-friendly and cost-effective. These technologies include the Internet of Things (IoT), Artificial Intelligence (AI), and Data Analytics. Either on their own or combined, they help companies switch to greener ways of working by providing insight into the nuts and bolts of operations.

Internet of Things (IoT)

IoT in manufacturing lets companies monitor operations in real-time by using smart sensors to track energy use and gain insight into how efficiently equipment is working. The insights allow companies to identify where and when to tweak processes and machines to optimize their performance, cutting down on waste and resource consumption. IoT devices are often tied into Energy Management and Information Systems (EMIS), like Stewwi, to provide a dashboard-like view of operations.

Artificial Intelligence (AI)

Artificial Intelligence helps make sense of all the data from IoT devices. AI algorithms can forecast when equipment might break down as part of a preventative maintenance program. This leads to less downtime and longer-lasting machines, making manufacturing more sustainable as the longevity of their equipment assets increase and operate at peak efficiency. In our experience, AI is best used as a support tool given it’s a nascent technology – a human review of the analysis and conclusions derived by AI is always recommended!

Data Analytics

Data Analytics is key in understanding the data from IoT and AI. It helps companies make choices that are better for the planet. By looking at the data, companies can spot where they can improve and make their supply chains and production better. As mentioned above, although data analytics is becoming more sophisticated, there is value in having a human take a second look at the findings.

Going Greener Today, for a Green Tomorrow

Using sustainable practices in making things is key for our planet and for business success. Your focus on green goals is vital for a bright future in eco-friendly production and business longevity. Going green not only helps the environment but also makes your operations more efficient and profitable over time, especially if you focus on addressing root causes first as in the above examples.